Firing and Press Furnaces

Features

-

ADVANCED PRESS™*

ADVANCED PRESS™* -

TTC-Mode

TTC-Mode -

Completely automatic, dynamic pressing power control

Completely automatic, dynamic pressing power control -

Z-Dry Mode

Z-Dry Mode

effective and time-saving -

Safety through PFC

Safety through PFC

(Power-Fail-Control) -

Full touch display and intuitive menu navigation

Full touch display and intuitive menu navigation -

EASY Light Display

EASY Light Display -

USB Port Download Service Centre

USB Port Download Service Centre

Features and their Properties

ADVANCED PRESS™ Process

The ADVANCED PRESS™ process ensures a uniform temperature

distribution from the temperature sensor of the pressing furnace to

the inside of the press ring. Pressing always takes place within the

ideal temperature range for pressing lithium disilicate. As a result,

this technology ensures perfect surfaces, minimal reaction layers and

extremely short pressing times.

TTC-mode enables linear cooling*

The ingenious software and the lift technology enable a linear cooling process when in TTC mode: In this programme, the user determines the freely selectable cooling rate after firering. Cracks in the ceramic or the dreaded „chipping“ are a thing of the past.

* available only in the VARIO PRESS 330.e ZR.

Completely automatic, dynamic pressing power control

The electronically controlled pressing power regulation

recognizes the required pressing forces during the working

process, depending on the geometry of the objects to be

pressed. In the case of diff erent volumes or thicknesses, the

VARIOPRESS 330 regulates the pressing power automatically

and dynamically during the entire working process. Finishing

the pressing process too early with the consequent defects

on the pressed objects is nearly impossible.

Z -Dry Mode - Eff ective and time-saving

A virtual sensor adjusts the lift position based on the

temperature in the fi ring chamber and automatically ensures

an ideal and constant pre-drying temperature of about 150°C

on the entire surface of the tray. This process prevents the

ceramic from cracks or bubbles.

Safety through PFC (Power-Fail-Control)

If the power goes out, PFC is activated! Once power is restored the oven operation is returned to the point of interruption.

USB Port Download Service Centre

After the successful registration of your VARIO PRESS 330 pressing

furnace in the service area of our Zubler homepage, you have access

to our extensive database. To download various programmes for all

dental ceramics on the market and the current software version for

your pressing furnace - simply log in and download.

In addition to the extended warranty, you will receive all services in

the download centre and you will always be technically up-to-date.

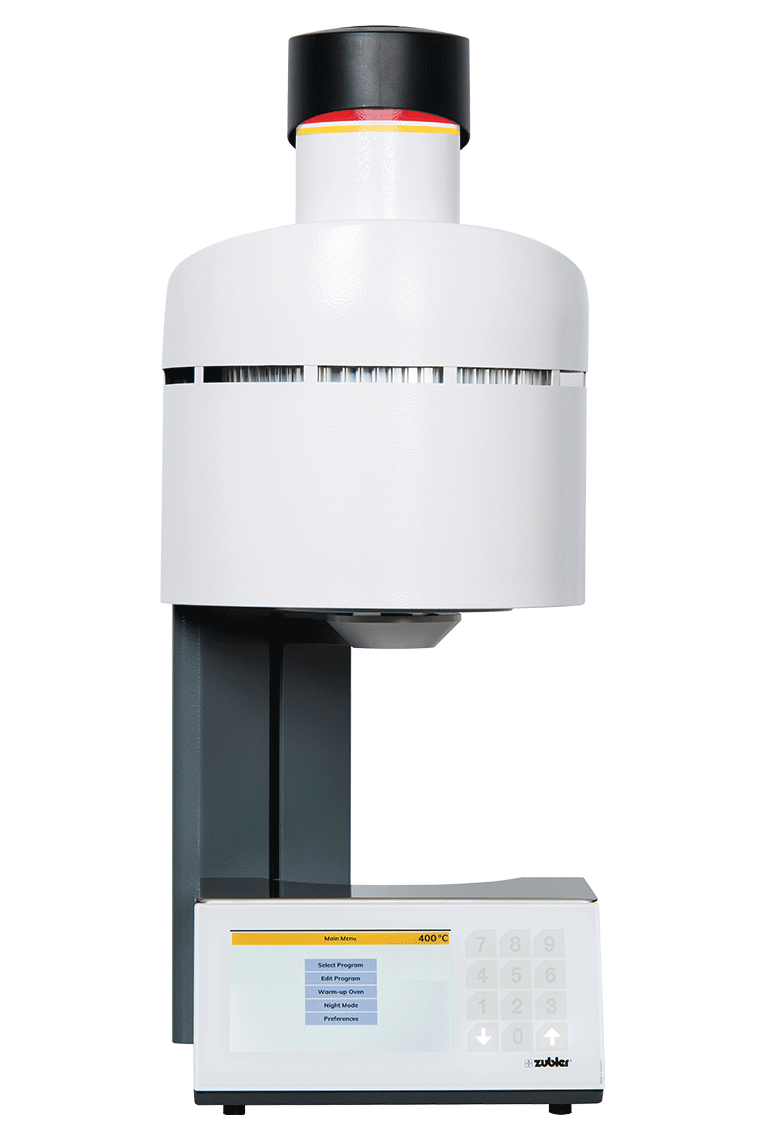

Full touch display and intuitive menu navigation

The VARIO PRESS 330 presents itself with a large and wellarranged

full touch display. The modern and contemporary

menu navigation represents more e ciency and operating

comfort. Whether editing for one-time a running programme or

permanently changing the programme parameters

- working with the VARIO PRESS 330 proves to be child‘s play.

EASY Light Display

Optimum visibility from all viewing angles – even at greater distances and under difficult lighting conditions such as bright sunshine.

With special technology for processing lithium disilicate ceramics!

-

ADVANCED PRESS™ process*

ADVANCED PRESS™ process*

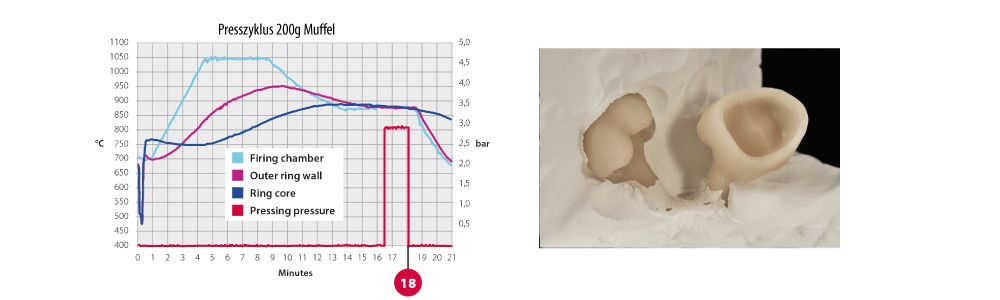

Graph 1 shows the temperature difference of approximately 40°C between the set temperature in the

pressing furnace and the inside temperature of the ring during standard pressing. The high temperature

difference between the ideal press temperature for lithium disilicate in the ring core and the high

temperature in the outside area of the ring, where the pressed objects are usually located, leads to a

strongly pronounced reaction layer. This effect is reinforced by the long holding and pressing time. The

result is a rough surface (orange peel) and time-consuming, laborious finishing.

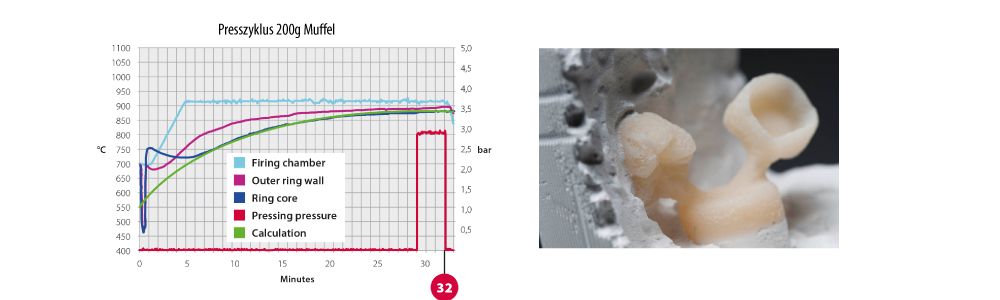

Graph 2 shows the homogeneous temperature distribution from the thermal sensor of the pressing furnace to the inside of the ring. There is a maximum temperature diff erence of 4°C. This ensures that all objects, regardless of their position in the ring, are pressed in the ideal pressing temperature range for lithium disilicate. The formation of a reaction layer is reduced to a minimum, and the extremely short pressing time further supports this eff ect. Smooth, homogeneous surfaces as well as enormous time saving in fi nishing and fi nalising the restoration are the result of ADVANCED PRESS™.

Graph 2 shows the homogeneous temperature distribution from the thermal sensor of the pressing furnace to the inside of the ring. There is a maximum temperature diff erence of 4°C. This ensures that all objects, regardless of their position in the ring, are pressed in the ideal pressing temperature range for lithium disilicate. The formation of a reaction layer is reduced to a minimum, and the extremely short pressing time further supports this eff ect. Smooth, homogeneous surfaces as well as enormous time saving in fi nishing and fi nalising the restoration are the result of ADVANCED PRESS™.

Graph1 | Standard Pressing Process:

The graph depicts the standard temperature difference between the interior of the ring and the chamber during a traditional press cycle, approximately 40°C. The vast temperature difference between the ideal pressing temperature for lithium disilicate in the ring core and the high temperature in outer regions of the ring, where the pressing objects are usually located, leads to a very distinct reaction layer. This effect is exacerbated by a lengthy hold time and a long press time. The result is a rough surface sometimes accompanied by an “orange peel” texture and laborious finishing work.

Graph2 | ADVANCED PRESS™ Process*

The graph shows the homogeneous temperature distribution from the temperature sensor of the press furnace to the interior of the ring. The maximum temperature difference is 4°C. This ensures that all objects, irrespective of their position in the ring, are pressed at the ideal pressing temperature. The formation of a reaction layer is reduced to a minimum and the extremely short pressing time further enhances this effect. The results of the ADVANCED PRESS™ are smooth and homogeneous surfaces along with an enormous time savings.